Polyacrylamide: A Comprehensive Guide on Definition, Classification, Applications, Mechanism of Action, Safety Considerations, Selection, Dissolution Methods, and Pricing.

Contents

- 1 Introduction

- 2 Definition: What is Polyacrylamide?

- 3 Classification of Polyacrylamide:

- 4 Diverse Applications of Polyacrylamide

- 5 Mechanism of Action: How PAM Works Its Magic

- 6 Safety Considerations When Working with Polyacrylamide

- 7 Selection of Polyacrylamide

- 8 Methods for Dissolving Polyacrylamide

- 9 Ensuring Full Dissolution of Polyacrylamide

- 10 Polyacrylamide Pricing

- 11 Does Using Polyacrylamide and Poly Aluminum Chloride Together Improve Efficiency?

- 11.1 The Role of Poly Aluminum Chloride in Water Treatment

- 11.2 The Role of Polyacrylamide in Water Treatment

- 11.3 Combined Use of PAC and PAM

- 11.4 Using polyacrylamide and poly aluminum chloride in tandem enhances the efficiency of wastewater treatment processes. By adjusting the pH and aiding coagulation, PAC prepares the water for effective flocculation by PAM, leading to faster and more efficient sedimentation. Always dissolve and add these agents separately to maximize their efficacy.

- 12 Conclusion: Polyacrylamide – A Remarkable Polymer

- 13 High-Performance PAM & PAC for Water Treatment

- 14 FAQs:

Introduction

In the realm of chemical compounds, polyacrylamide (PAM) stands out as a versatile and widely used substance. This blog post provides a comprehensive overview of polyacrylamide, including its definition, classification, applications across various industries, mechanism of action, important safety considerations, selection criteria, dissolution methods, and pricing. Whether you are new to polyacrylamide or looking to deepen your understanding, this guide will offer valuable insights into this essential chemical.

Definition: What is Polyacrylamide?

Polyacrylamide, commonly referred to as PAM, is a synthetic water-soluble polymer. It is derived from the monomer acrylamide through polymerization. PAM is known for its unique properties, such as high water solubility, flocculation capability, and viscosity control.

Classification of Polyacrylamide:

Polyacrylamides can be classified into different types based on their charge properties and molecular weight, categorized primarily by their:

Ionic Charge:

- Anionic Polyacrylamide (APAM): APAM contains negatively charged groups, making it highly effective in flocculation and sedimentation processes. It is commonly used in wastewater treatment, mineral processing, and the oil and gas industry.

- Cationic Polyacrylamide (CPAM): CPAM carries positive charges, making it suitable for applications such as sludge dewatering, papermaking, and wastewater treatment. It exhibits excellent coagulation and dewatering properties.

- Nonionic Polyacrylamide (NPAM): NPAM has no charged groups and is typically used for applications that require water-soluble polymers without ionic properties. It finds usage in industries like agriculture, textile, and papermaking.

- Amphoteric Polyacrylamide (AmPAM): AmPAM contains both positive and negative charged groups. It exhibits versatile properties and can be used in a wide range of applications, including water treatment, oil recovery, and papermaking.

Molecular Weight:

- High Molecular Weight (HMW) PAM: Forms large, strong flocs for efficient settling of suspended solids.

- Low Molecular Weight (LMW) PAM: Acts as a thickening agent and drag reducer in various applications.

Diverse Applications of Polyacrylamide

Polyacrylamide finds extensive applications across various industries, thanks to its unique properties. Some notable applications include:

- Water Treatment: PAM is widely used in water treatment processes such as coagulation, flocculation, and sedimentation. It aids in the removal of suspended solids, organic matter, and contaminants, improving water quality.

- Enhanced Oil Recovery (EOR): In the oil and gas industry, PAM is utilized for EOR techniques. It improves oil recovery by enhancing the viscosity of injected water and reducing the mobility of oil.

- Papermaking: Polyacrylamide is employed in the papermaking process to improve drainage, retention, and strength properties of paper. It enhances the efficiency of paper production and reduces the environmental impact.

- Agriculture: PAM is used in agriculture to improve soil structure and water retention. It reduces soil erosion, enhances water infiltration, and promotes efficient water use, leading to increased crop yield.

- Textile Industry: PAM finds application in the textile industry for fabric sizing, dyeing, and printing. It improves the quality of textiles and enhances color fastness.

- Mining: Used in mineral processing for flocculation and improving separation efficiency.

- Wastewater Treatment: Improves settling of sludge in wastewater treatment plants.

- Food Processing: Thickening agent in various food products, aiding in texture and mouthfeel.

Mechanism of Action: How PAM Works Its Magic

Polyacrylamide’s effectiveness lies in its ability to interact with water molecules and other suspended particles. Here’s how it works in different scenarios:

- Flocculation: In water treatment, PAM bridges suspended particles through hydrogen bonding with water molecules and electrostatic interactions with the particles themselves. This bridging creates larger flocs that settle more readily, aiding in water clarification.

- Thickening: High molecular weight PAMs entangle water molecules, increasing the viscosity of a solution. This thickening property finds use in various applications, such as drilling fluids, food additives, and wastewater treatment.

- Drag Reduction: Certain PAMs reduce frictional drag between liquids and solid surfaces. This property translates to energy savings in pipelines transporting fluids like oil or water.

- Soil Conditioning: PAM can improve water retention in soil and reduce erosion. This makes it beneficial for agriculture and landscaping applications.

Safety Considerations When Working with Polyacrylamide

While polyacrylamide is a valuable chemical compound, it is essential to consider safety precautions when handling and using it. Some important safety considerations include:

- Proper handling: Follow recommended handling procedures, including wearing appropriate protective equipment, such as gloves and goggles.

- Storage: Store polyacrylamide in a cool and dry place, away from direct sunlight and incompatible substances.

- Disposal: Dispose of polyacrylamide waste properly, following local regulations and guidelines.

- Skin and eye contact: Avoid direct contact with polyacrylamide. In case of contact, rinse the affected area with plenty of water and seek medical attention if necessary.

- Inhalation: Minimize inhalation of polyacrylamide dust or fumes. Ensure proper ventilation in the working area.

Selection of Polyacrylamide

Choosing the right type of polyacrylamide is one of the most common challenges in wastewater treatment. This issue has long troubled countless users. With over 30 different types of polyacrylamide, users face the problem of selecting the most effective and cost-efficient model. However, for those who truly understand polyacrylamide, the selection process becomes much simpler.

Matching Polyacrylamide to Water Quality

Different types of water require different types of polyacrylamide:

- Acidic and Neutral Water: Typically, cationic polyacrylamide is used.

- Organic Wastewater: Cationic polyacrylamide is commonly chosen.

- Urban Sewage Sludge Dewatering: Cationic polyacrylamide is preferred.

- Neutral and Alkaline Water: Anionic polyacrylamide is often used.

- Acidic or Near Neutral Water: Nonionic polyacrylamide is generally selected.

Selecting Polyacrylamide for Different Treatment Stages

- Primary and Secondary Sedimentation Tanks: Anionic or nonionic polyacrylamide is usually chosen.

- Sludge Dewatering: Cationic polyacrylamide is commonly used.

Choosing Polyacrylamide for Different Sludge Dewatering Equipment

- Plate and Frame Filter Press: Often used with cationic polyacrylamide of 20-30 ionicity, and sometimes with lower ionicity cationic or anionic polyacrylamide.

- Belt Filter Press: Commonly paired with cationic polyacrylamide of 20-50 ionicity.

- Centrifugal Filter: Typically used with cationic polyacrylamide of 30-60 ionicity.

- Screw Press: Often used with cationic polyacrylamide of 20-60 ionicity, and occasionally with anionic polyacrylamide. In some cases, polyacrylamide may not be necessary.

The Most Scientific and Accurate Selection Method

In the water treatment industry, the most scientific and accurate method for selecting the right type of polyacrylamide involves several steps:

- Analyze the Characteristics of the Industry: Understand the specific needs based on industry standards.

- Test the Water Quality: Conduct thorough water quality tests.

- Compare Multiple Models: Test various polyacrylamide models to compare their effectiveness and dosage.

- Determine the Optimal Model: Select the polyacrylamide that offers the best treatment results with the least amount required.

This method ensures that the selection of polyacrylamide is both scientifically sound and highly accurate.

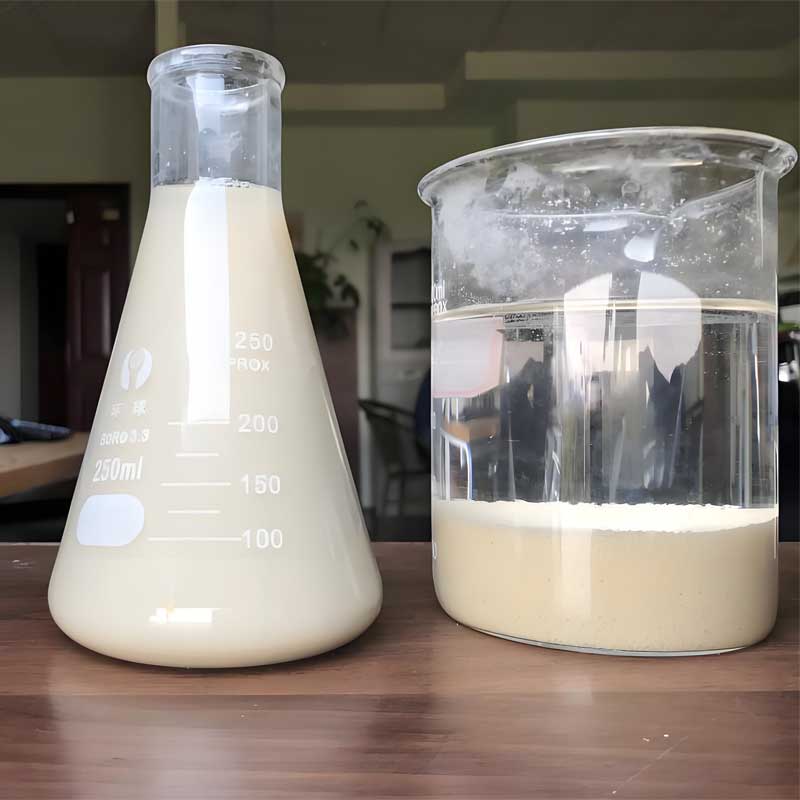

Methods for Dissolving Polyacrylamide

- Dissolution with Tap Water: Dissolve polyacrylamide (PAM) using tap water at room temperature. Typically, anionic and nonionic flocculants are dissolved at a concentration of 0.1%, while cationic flocculants are dissolved at 0.2%. Raising the water temperature can slightly enhance the dissolution process, but it should not exceed 50°C to avoid thermal degradation of PAM, which could negatively impact its effectiveness.

- Initial Water Addition: Fill the dissolution tank with water up to half of its volume.

- Stirring: Turn on the agitator and begin stirring. Gradually and steadily add the accurately weighed flocculant along the vortex edge created by the stirring. Add water to reach the specified volume and adjust to the desired concentration. Continue stirring until PAM is completely dissolved.

- Stirring Speed: The optimal stirring speed is between 200 to 400 revolutions per minute (RPM). Excessive speed might damage the PAM molecules.

- Stirring Duration: PAM generally requires about an hour of stirring to fully dissolve the powder. Incomplete dissolution or clumping can adversely affect its performance, potentially causing sedimentation, clogging of pipes, and dosing pumps.

- Pump Usage: Avoid using centrifugal pumps to convey the solution and do not use gear pumps, as they can reduce the molecular weight of the solution during transportation. Use the prepared solution within 48 hours after dissolution.

Ensuring Full Dissolution of Polyacrylamide

To ensure complete dissolution of polyacrylamide, consider the following methods:

- Heating Tap Water: Use tap water when dissolving polyacrylamide. If conditions allow, slightly heating the tap water can accelerate the dissolution process. (Note: Heat the water moderately, as excessive heat can damage the molecular structure of polyacrylamide.)

- Using Water-Soluble Alcohol: Dissolve PAM in water-soluble alcohol before adding it to water. First, disperse the polyacrylamide in the alcohol, then stir it into water. This method can significantly increase the dissolution rate of polyacrylamide.

Polyacrylamide Pricing

Polyacrylamide (PAM) can be classified into four types based on its ionic nature: cationic polyacrylamide, anionic polyacrylamide, nonionic polyacrylamide, and amphoteric polyacrylamide. The pricing of these types varies based on their specific properties.

- Cationic Polyacrylamide (CPAM): The price of cationic polyacrylamide is determined by its ionicity. Higher ionicity corresponds to a higher price. Cationic polyacrylamide typically has an ionicity range of 5-60%. In the current market, cationic polyacrylamide with 60% ionicity costs over ¥23,000 per ton. Prices decrease as ionicity decreases. For instance, CPAM with 30% ionicity is around ¥20,000 per ton, while those with ionicity below 20% are priced under ¥20,000 per ton.

- Anionic Polyacrylamide (APAM): The price of anionic polyacrylamide increases with its molecular weight. Sezoe Envirotech’s APAM has a molecular weight range of 6-18 million. APAM with an 18 million molecular weight is priced around ¥14,000-15,000 per ton, whereas lower molecular weight variants are priced in the range of several thousand yuan.

- Nonionic Polyacrylamide (NPAM): The pricing for nonionic polyacrylamide is also based on molecular weight, ranging from 4-12 million. NPAM with a 12 million molecular weight is slightly more expensive than APAM with an 18 million molecular weight. Lower molecular weight NPAMs are priced in the range of several thousand yuan.

- Amphoteric Polyacrylamide (AmPAM): Although not widely used, the pricing of amphoteric polyacrylamide is similar to that of anionic polyacrylamide.

The prices mentioned above are indicative and may vary depending on the manufacturer. Therefore, it is recommended to compare the quality of polyacrylamide products from different manufacturers before considering the price.

Does Using Polyacrylamide and Poly Aluminum Chloride Together Improve Efficiency?

In wastewater treatment, using a single chemical agent often does not achieve optimal results. Combining polyacrylamide (PAM) and poly aluminum chloride (PAC) can significantly enhance treatment effectiveness.

The Role of Poly Aluminum Chloride in Water Treatment

Poly aluminum chloride has two primary functions in water treatment:

- pH Adjustment: PAC can adjust the pH of water to a range of 6-9, which is ideal for subsequent treatment with PAM and other agents.

- Coagulation Aid: PAC helps form flocculent clumps in the water, making it easier for PAM to bind these clumps together for faster sedimentation. When PAC is used alone, it produces flocculent particles, but these settle very slowly, often floating on the water surface and causing turbidity. Thus, using PAC alone is generally not very effective.

The Role of Polyacrylamide in Water Treatment

PAM acts primarily as a flocculant, aiding in the aggregation and sedimentation of suspended particles. When used alone, PAM can effectively clean wastewater if the pH is within the 6-9 range. However, if the water’s pH falls outside this range or if the water quality is particularly complex, PAM’s effectiveness may be compromised.

Combined Use of PAC and PAM

Experienced wastewater treatment professionals know that PAC and PAM are rarely used independently in practice. For optimal results, they should be dissolved and added separately:

- Dissolve and Add PAC: Start by adding the PAC solution to the water. PAC adjusts the pH and initiates coagulation.

- Dissolve and Add PAM: After PAC, add the PAM solution. PAM will then bind the coagulated particles together, facilitating rapid sedimentation.

This method ensures the best results with minimal chemical usage. It is crucial not to mix PAC and PAM during dissolution, as this can cause a reaction that reduces their effectiveness.

Using polyacrylamide and poly aluminum chloride in tandem enhances the efficiency of wastewater treatment processes. By adjusting the pH and aiding coagulation, PAC prepares the water for effective flocculation by PAM, leading to faster and more efficient sedimentation. Always dissolve and add these agents separately to maximize their efficacy.

Conclusion: Polyacrylamide – A Remarkable Polymer

Polyacrylamide (PAM) is a versatile chemical compound with a wide range of applications. Its various classifications, including anionic, cationic, nonionic, and amphoteric, enable its usage in diverse industries. PAM plays a crucial role in water treatment, oil recovery, agriculture, and papermaking, among other fields. Understanding its mechanism of action and following safety considerations is vital for maximizing its benefits while ensuring safe handling anddisposal. Polyacrylamide continues to be a valuable tool in industries worldwide, contributing to improved water quality, enhanced oil recovery, sustainable agriculture, and efficient paper production.

High-Performance PAM & PAC for Water Treatment

- Solve Your Water Treatment Challenges: WaterCareChem is your one-stop shop for premium Polyacrylamide (PAM) and Poly Aluminum Chloride (PAC).

- Factory-Direct Expertise: As a trusted manufacturer specializing in PAM and PAC, we offer unmatched quality and technical support.

- Unparalleled Performance: Our rigorously tested products ensure exceptional stability and effectiveness for optimal water clarification and purification.

- Reliable Partnership: WaterCareChem is committed to exceeding your expectations. We provide dependable service and top-notch solutions to meet your specific water treatment needs.

- Request a Quote Today! Let us help you achieve cleaner, clearer water.

FAQs:

- Is polyacrylamide safe for water treatment?

Yes, when used according to recommended guidelines, polyacrylamide is safe for water treatment. It aids in removing impurities and improving water quality.

- Can polyacrylamide be used in drinking water treatment?

Polyacrylamide can be used in drinking water treatment; however, it is crucial to ensure proper dosage and compliance with regulatory standards.

- Are there any environmental concerns associated with polyacrylamide?

Polyacrylamide itself is not considered harmful to the environment. However, it is crucial to handle and dispose of it properly to prevent any negative impact.

- Can polyacrylamide be used in organic farming?

Polyacrylamide can be used in organic farming as long as it complies with organic certification standards and is used in a manner that aligns with organic farming principles.

- Is polyacrylamide biodegradable?

Polyacrylamide is not readily biodegradable. However, it can undergo degradation over time under certain conditions, such as exposure to sunlight and microbial activity.

Last Updated on 2024-07-05 by system